Aluminium Loading Ramps / Van Ramps Foot End

Most TUV Certified (https://www.tuv.com/world/en/) loading ramps are designed, tested & built at a 30% loading gradient to allow for safe loading & unloading.

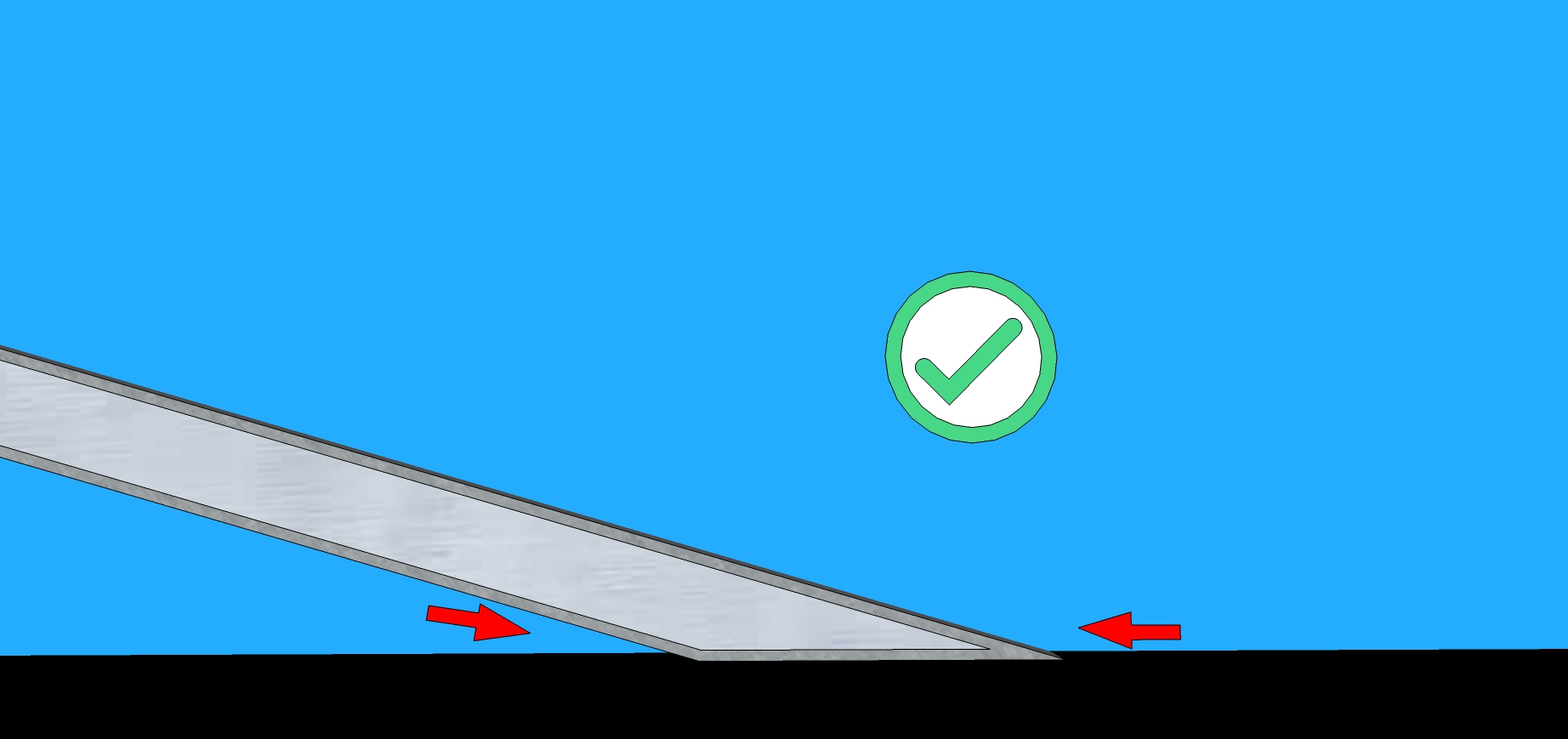

Because all of our Plant Ramps and Van Ramps (except the TRP40 Series) have a foot end cut to sit flat on the floor when the ramp is used at a specific angle - This is to evenly distribute the weight applied & allow for a smooth transfer on or off the ramp at ground level.

If the height you are loading to differs from the product specification, we recommend speaking to one of our advisers. It could be that a customised ramp solution will need to be fabricated at our factory to suit the height you are loading up to. Price for amending the foot end is typically £50 plus VAT for a pair of loading ramps.

-Foot End on Tip = ramp height is too high (this can cause the ramps life to be reduced and for the tip of the ramp to wear down faster than normal usage)

-Foot End on Tip = ramp height is too high (this can cause the ramps life to be reduced and for the tip of the ramp to wear down faster than normal usage) -Foot End Pushed Forward = ramp height is too low (this can cause the ramp to flip up/stand upright to the height it is cut for - one solution is to use wooden chocks to support the ramp – please speak to an advisor for assistance on this)

-Foot End Pushed Forward = ramp height is too low (this can cause the ramp to flip up/stand upright to the height it is cut for - one solution is to use wooden chocks to support the ramp – please speak to an advisor for assistance on this)

All loading ramps held in stock for next day delivery will be cut for the 30% gradient which translates as follows:

1500mm length = 450mm load height 2000mm length = 600mm load height 2500mm length = 750mm load height 3000mm length = 900mm load height 3500mm length = 1050mm load height 4000mm length = 1200mm load height 4500mm length = 1350mm load height 5000mm length = 1500mm load height Having the foot end cut to sit flush with the ground will increase the life expectancy of your loading ramps & make for smoother loading. Using a ramp at the wrong height is likely to invalidate warranty & be very dangerous. Please see the 3 images below showing: -Foot End Flush = ramp at correct height – this is how the ramp is designed to be used -Foot End on Tip = ramp height is too high (this can cause the ramps life to be reduced and for the tip of the ramp to wear down faster than normal usage)

-Foot End on Tip = ramp height is too high (this can cause the ramps life to be reduced and for the tip of the ramp to wear down faster than normal usage) -Foot End Pushed Forward = ramp height is too low (this can cause the ramp to flip up/stand upright to the height it is cut for - one solution is to use wooden chocks to support the ramp – please speak to an advisor for assistance on this)

-Foot End Pushed Forward = ramp height is too low (this can cause the ramp to flip up/stand upright to the height it is cut for - one solution is to use wooden chocks to support the ramp – please speak to an advisor for assistance on this)

Related Products

Extra Wide Aluminium Loading Ramp (3000x400x4500kg)

£1,062.00

£885.00

Extra Wide Aluminium Loading Ramp (3500x400x3000kg)

£1,212.00

£1,010.00

Aluminium Loading Ramps (4000x510x8870kg)

£2,310.00

£1,925.00

Aluminium Loading Ramps (4500x510x7100kg)

£2,754.00

£2,295.00

Aluminium Loading Ramps (5000x510x5910kg)

£3,114.00

£2,595.00

Aluminium Loading Ramps (5500mmx510x5072kg)

£3,246.00

£2,705.00

Extra Wide Aluminium Loading Ramps (1500x500x2450kg)

£678.00

£565.00

Aluminium Loading Ramps (2000x300x3500kg)

£732.00

£610.00

Aluminium Loading Ramps (2500x400x7000kg)

£1,248.00

£1,040.00

Extra Wide Aluminium Loading Ramps (2500x460x7000kg)

£1,290.00

£1,075.00

Aluminium Loading Ramps (2500x510x12000kg)

£1,728.00

£1,440.00

Aluminium Loading Ramps (2500x300x3200kg)

£804.00

£670.00

Extra Wide Aluminium Loading Ramps (2500x400x6000kg)

£1,056.00

£880.00

Extra Wide Aluminium Loading Ramps (2500x400x3800kg)

£876.00

£730.00

Extra Wide Aluminium Loading Ramps (2500x400x5000kg)

£942.00

£785.00

Aluminium Loading Ramps (2500x400x8000kg)

£1,290.00

£1,075.00

Extra Wide Aluminium Loading Ramps (2500x460x10000kg)

£1,380.00

£1,150.00

Aluminium Loading Ramps (2500x510x10000kg)

£1,614.00

£1,345.00

Aluminium Loading Ramps (2500x550x18000kg)

£1,938.00

£1,615.00

Aluminium Loading Ramps (2500x550x20000kg)

£2,166.00

£1,805.00

Aluminium Loading Ramps (2500x580x14000kg)

£2,016.00

£1,680.00

Aluminium Loading Ramps (3000x400x7000kg)

£1,392.00

£1,160.00

Extra Wide Aluminium Loading Ramps (3000x480x7000kg)

£1,452.00

£1,210.00

Aluminium Loading Ramps (3000x300x1330kg)

£798.00

£665.00

Aluminium Loading Ramps (3000x360x6000kg)

£1,146.00

£955.00

Extra Wide Aluminium Loading Ramps (3000x400x2500kg)

£948.00

£790.00

Extra Wide Aluminium Loading Ramps (3000x400x6000kg)

£1,176.00

£980.00

Aluminium Loading Ramps (3000x400x8000kg)

£1,446.00

£1,205.00

Extra Wide Aluminium Loading Ramps (3000x460x8500kg)

£1,542.00

£1,285.00

Aluminium Loading Ramps (3000x580x14000kg)

£2,334.00

£1,945.00

Extra Wide Aluminium Loading Ramps (3000x510x12650kg)

£1,782.00

£1,485.00

Aluminium Loading Ramps (3000x510x10000kg)

£1,764.00

£1,470.00

Aluminium Loading Ramps (3000x550x18000kg)

£2,274.00

£1,895.00

Aluminium Loading Ramps (3000x550x19000kg)

£2,460.00

£2,050.00

Aluminium Loading Ramps (3000x580x16000kg)

£2,556.00

£2,130.00

Extra Wide Aluminium Loading Ramps (3500x480x5540kg)

£1,512.00

£1,260.00

Aluminium Loading Ramps (3500x510x12000kg)

£2,196.00

£1,830.00

Aluminium Loading Ramps (3500x300x1750kg)

£1,020.00

£850.00

Aluminium Loading Ramps (3500x360x3000kg)

£1,158.00

£965.00

Aluminium Loading Ramps (3500x360x4580kg)

£1,254.00

£1,045.00

Extra Wide Aluminium Loading Ramps (3500x400x1900kg)

£1,044.00

£870.00

Extra Wide Aluminium Loading Ramps (3500x400x4580kg)

£1,296.00

£1,080.00

Aluminium Loading Ramps (3500x400x6870kg)

£1,554.00

£1,295.00

Extra Wide Aluminium Loading Ramps (3500x460x6870kg)

£1,620.00

£1,350.00

Extra Wide Aluminium Loading Ramps (3500x510x8430kg)

£1,794.00

£1,495.00

Aluminium Loading Ramps (3500x510x9600kg)

£1,950.00

£1,625.00

Aluminium Loading Ramps (3500x550x18000kg)

£2,754.00

£2,295.00

Aluminium Loading Ramps (3500x580x14000kg)

£2,526.00

£2,105.00

Aluminium Loading Ramps (3500x580x16000kg)

£2,766.00

£2,305.00

Extra Wide Aluminium Loading Ramps (4000x480x4155kg)

£1,614.00

£1,345.00

Aluminium Loading Ramps (4000x300x1400kg)

£1,086.00

£905.00

Aluminium Loading Ramps (4000x300x1000kg)

£1,020.00

£850.00

Aluminium Loading Ramps (4000x360x1500kg)

£1,158.00

£965.00

Aluminium Loading Ramps (4000x360x2500kg)

£1,236.00

£1,030.00

Aluminium Loading Ramps (4000x360x3435kg)

£1,326.00

£1,105.00

Extra Wide Aluminium Loading Ramps (4000x400x1500kg)

£1,194.00

£995.00

Extra Wide Aluminium Loading Ramps (4000x400x2500kg)

£1,296.00

£1,080.00

Extra Wide Aluminium Loading Ramps (4000x400x3435kg)

£1,392.00

£1,160.00

Aluminium Loading Ramps (4000x510x7200kg)

£2,172.00

£1,810.00

Aluminium Loading Ramps (4000x580x10620kg)

£2,724.00

£2,270.00

Aluminium Loading Ramps (4000x580x15010kg)

£2,700.00

£2,250.00

Aluminium Loading Ramps (4500x300x1050kg)

£1,452.00

£1,210.00

Aluminium Loading Ramps (4500x400x2770kg)

£1,854.00

£1,545.00

Extra Wide Aluminium Loading Ramps (4500x480x3325kg)

£2,034.00

£1,695.00

Aluminium Loading Ramps (4500x300x830kg)

£1,224.00

£1,020.00

Aluminium Loading Ramps (4500x360x1250kg)

£1,314.00

£1,095.00

Aluminium Loading Ramps (4500x360x1800kg)

£1,368.00

£1,140.00

Aluminium Loading Ramps (4500x360x2750kg)

£1,554.00

£1,295.00

Extra Wide Aluminium Loading Ramps (4500x400x1250kg)

£1,494.00

£1,245.00

Extra Wide Aluminium Loading Ramps (4500x400x1800kg)

£1,554.00

£1,295.00

Extra Wide Aluminium Loading Ramps (4500x400x2750kg)

£1,614.00

£1,345.00

Aluminium Loading Ramps (4500x400x4120kg)

£1,974.00

£1,645.00

Aluminium Loading Ramps (4500x510x5760kg)

£2,304.00

£1,920.00

Aluminium Loading Ramps (4500x580x12000kg)

£3,300.00

£2,750.00

Aluminium Loading Ramps (4500x580x8500kg)

£3,054.00

£2,545.00

Aluminium Loading Ramps (5000x400x2770kg)

£2,274.00

£1,895.00

Aluminium Loading Ramps (5000x480x2770kg)

£2,454.00

£2,045.00

Aluminium Loading Ramps (5000x580x10000kg)

£3,834.00

£3,195.00

Aluminium Loading Ramps (5000x360x1070kg)

£1,674.00

£1,395.00

Aluminium Loading Ramps (5000x360x1500kg)

£1,794.00

£1,495.00

Aluminium Loading Ramps (5000x360x2290kg)

£1,914.00

£1,595.00

Aluminium Loading Ramps (5000x400x1070kg)

£1,686.00

£1,405.00

Aluminium Loading Ramps (5000x400x1500kg)

£1,914.00

£1,595.00

Aluminium Loading Ramps (5000x400x2290kg)

£2,034.00

£1,695.00

Aluminium Loading Ramps (5000x510x4800kg)

£2,754.00

£2,295.00

Aluminium Loading Ramps (5000x580x7080kg)

£3,294.00

£2,745.00

Aluminium Loading Ramps (5500x510x4110kg)

£3,000.00

£2,500.00

Aluminium Loading Ramps (5500x580x6070kg)

£3,564.00

£2,970.00

Aluminium Loading Ramps (5500x580x8570kg)

£4,140.00

£3,450.00

Aluminium Loading Ramps Extra Wide (2500x500x2000kg)

£852.00

£710.00

Extra Wide Aluminium Loading Ramps (3000x500x1330kg)

£990.00

£825.00

Heavy Duty Loading Ramps for Steel Tracks (1000mm x 450mm x 50,000kg)

£1,860.00

£1,550.00

Heavy Duty Loading Ramps for Steel Tracks (1000mm x 600mm x 58,000kg)

£2,214.00

£1,845.00

Heavy Duty Loading Ramps for Steel Tracks (1500mm x 450mm x 40,000kg)

£2,232.00

£1,860.00

Heavy Duty Loading Ramps for Steel Tracks (1500mm x 600mm x 50,000kg)

£2,706.00

£2,255.00

Heavy Duty Loading Ramps for Steel Tracks (2000mm x 450mm x 40,000kg)

£2,754.00

£2,295.00

Heavy Duty Loading Ramps for Steel Tracks (2000mm x 600mm x 50,000kg)

£3,342.00

£2,785.00

Heavy Duty Loading Ramps for Steel Tracks (2500mm x 450mm x 34,000kg)

£3,150.00

£2,625.00

Heavy Duty Loading Ramps for Steel Tracks (2500mm x 600mm x 48,000kg)

£3,858.00

£3,215.00

Heavy Duty Loading Ramps for Steel Tracks (3000mm x 450mm x 26,200kg)

£3,546.00

£2,955.00

Heavy Duty Loading Ramps for Steel Tracks (3000mm x 600mm x 36,000kg)

£4,368.00

£3,640.00

Heavy Duty Loading Ramps for Steel Tracks (3500mm x 450mm x 18,000kg)

£3,942.00

£3,285.00

Heavy Duty Loading Ramps for Steel Tracks (3500mm x 600mm x 26,100kg)

£4,878.00

£4,065.00

Heavy Duty Loading Ramps for Steel Tracks (4000mm x 450mm x 14,000kg)

£4,338.00

£3,615.00

Heavy Duty Loading Ramps for Steel Tracks (4000mm x 600mm x 19,000kg)

£5,388.00

£4,490.00

Heavy Duty Loading Ramps for Steel Tracks (4500mm x 450mm x 10,500kg)

£4,740.00

£3,950.00

Heavy Duty Loading Ramps for Steel Tracks (4500mm x 600mm x 12,000kg)

£5,898.00

£4,915.00

Heavy Duty Loading Ramps for Steel Tracks (5000mm x 450mm x 8,500kg)

£5,184.00

£4,320.00

Heavy Duty Loading Ramps for Steel Tracks (5000mm x 600mm x 10,500kg)

£6,462.00

£5,385.00

Viper Premium Heavy Duty Van Ramp 1000mm wide x 2000kg Capacity

From

£1,062.00

£885.00

Ramps for Steel Tracks with Rubber Coating (2000mm x 720mm x 26.300kg)

£3,498.00

£2,915.00

Ramps for Steel Tracks with Rubber Coating (2500mm x 720mm x 26,300kg)

£4,098.00

£3,415.00

Ramps for Steel Tracks with Rubber Coating (2500mm x 480mm x 17,500kg)

£3,018.00

£2,515.00

Ramps for Steel Tracks with Rubber Coating (2500mm x 480mm x 17.500kg)

£2,880.00

£2,400.00

Ramps for Steel Tracks with Rubber Coating (3000mm x 480mm x 17.500kg)

£3,414.00

£2,845.00

Ramps for Steel Tracks with Rubber Coating (3000mm x 720mm x 26.300kg)

£4,698.00

£3,915.00

Ramps for Steel Tracks with Rubber Coating (3500mm x 480mm x 12.766kg)

£3,966.00

£3,305.00

Ramps for Steel Tracks with Rubber Coating (3500mm x 720mm x 19.149kg)

£5,448.00

£4,540.00

Ramps for Steel Tracks with Rubber Coating (4000mm x 480mm x 9574kg)

£4,512.00

£3,760.00

Ramps for Steel Tracks with Rubber Coating (4000mm x 720mm x 14.362kg)

£6,192.00

£5,160.00

Ramps for Steel Tracks with Rubber Coating (4500mm x 480mm x 7659kg)

£5,058.00

£4,215.00

Ramps for Steel Tracks with Rubber Coating (4500mm x 720mm x 11.489kg)

£7,050.00

£5,875.00

Ramps for Steel Tracks with Rubber Coating (5000mm x 480mm x 6383kg)

£5,694.00

£4,745.00

Ramps for Steel Tracks with Rubber Coating (5000mm x 720mm x 9574kg)

£7,914.00

£6,595.00

Ramps for Steel Tracks with Rubber Coating (5500mm x 480mm x 5471kg)

£6,366.00

£5,305.00

Ramps for Steel Tracks with Rubber Coating (5500mm x 720mm x 8207kg)

£8,694.00

£7,245.00

TRP150/40 Aluminium Loading Ramps (4000x400x5150kg)

£1,620.00

£1,350.00

TRP150/50 Aluminium Loading Ramps (5000mmx400mmx3435kg)

£2,274.00

£1,895.00

Aluminium Loading Ramps (2500x580x16000kg)

£2,334.00

£1,945.00

Aluminium Loading Ramps (3500x300x1000kg)

£852.00

£710.00

Extra Wide Aluminium Loading Ramps (3500x500x1000kg)

£1,056.00

£880.00

Aluminium Loading Ramps (4000x300x800kg)

£978.00

£815.00

Extra Wide Aluminium Loading Ramps (4000x500x800kg)

£1,194.00

£995.00

Aluminium Loading Ramps (3500x300x1250kg)

£972.00

£810.00

PAIR of ALUMINIUM RAMPS (105X390X1000 - 21500kg) Standard. Milled surface

£1,476.00

£1,230.00

PAIR of ALUMINIUM RAMPS (105X390X1500 -21500kg ) Standard. Milled surface

£1,740.00

£1,450.00

PAIR of ALUMINIUM RAMPS (105X390X2000 -21500kg) Standard. Milled surface

£1,920.00

£1,600.00

PAIR of ALUMINIUM RAMPS (105X390X2500 -18000 kg) Standard. Milled surface

£2,160.00

£1,800.00

PAIR of ALUMINIUM RAMPS (105X390X3000 - 13720 kg) Standard. Milled surface

£2,520.00

£2,100.00

PAIR of ALUMINIUM RAMPS (105X390X3500 - 9145kg Standard. Milled surface

£2,880.00

£2,400.00

PAIR of ALUMINIUM RAMPS (105X390X4000 - 6860kg) Standard. Milled surface

£3,120.00

£2,600.00

PAIR of ALUMINIUM RAMPS (105X390X4500 - 5485kg) Standard. Milled surface

£3,360.00

£2,800.00

PAIR of ALUMINIUM RAMPS (105X390X5000 -4575kg) Standard. Milled surface

£3,600.00

£3,000.00

PAIR of ALUMINIUM RAMPS (105X520X1000 - 2900kg) Standard. Milled surface

£1,860.00

£1,550.00

PAIR of ALUMINIUM RAMPS (105X520X1500 - 2900kg) Standard. Milled surface

£2,340.00

£1,950.00

PAIR of ALUMINIUM RAMPS (105X520X2000 - 2900kg) Standard. Milled surface

£2,520.00

£2,100.00

PAIR of ALUMINIUM RAMPS (105X520X2500 -22000 kg) Standard. Milled surface

£2,700.00

£2,250.00

PAIR of ALUMINIUM RAMPS (105X520X3000 - 18290 kg) Standard. Milled surface

£2,820.00

£2,350.00

PAIR of ALUMINIUM RAMPS (105X520X3500 - 12195kg) Standard. Milled surface

£3,180.00

£2,650.00

PAIR of ALUMINIUM RAMPS (105X520X4000 - 9145kg) Standard. Milled surface

£3,600.00

£3,000.00

PAIR of ALUMINIUM RAMPS (105X520X4500 - 7315kg) Standard. Milled surface

£4,200.00

£3,500.00

PAIR of ALUMINIUM RAMPS (105X520X5000 -6095kg) Standard. Milled surface

£4,380.00

£3,650.00

Aluminium Loading Ramps (2500x460x9000kg)

£1,428.00

£1,190.00

Aluminium Loading Ramps (3000x460x9000kg)

£1,620.00

£1,350.00

Aluminium Loading Ramps (3500x460x8430kg)

£1,740.00

£1,450.00

Aluminium Loading Ramps (4000x460x6320kg)

£1,866.00

£1,555.00

Aluminium Loading Ramps (4500x460x5060kg)

£2,130.00

£1,775.00

Aluminium Loading Ramps (5000x460x4210kg)

£2,634.00

£2,195.00

Extra Wide Aluminium Loading Ramps (2500x510x9000kg)

£1,470.00

£1,225.00

Extra Wide Aluminium Loading Ramps (3000x510x9000kg)

£1,662.00

£1,385.00

Extra Wide Aluminium Loading Ramps (3500x510x8430kg)

£1,794.00

£1,495.00

Extra Wide Aluminium Loading Ramps (4000x510x6320kg)

£1,980.00

£1,650.00

Extra Wide Aluminium Loading Ramps (4500x510x5060kg)

£2,274.00

£1,895.00

Aluminium Loading Ramps (5000x510x4210kg)

£2,514.00

£2,095.00

Aluminium Loading Ramps (2500x360x5000kg)

£924.00

£770.00

Aluminium Loading Ramps (2500x360x6000kg)

£1,038.00

£865.00

Aluminium Loading Ramps (2000x300x3000kg)

£648.00

£540.00

Aluminium Loading Ramps (2500x300x2510kg)

£702.00

£585.00

Aluminium Loading Ramps (3000x300x1670kg)

£834.00

£695.00

Aluminium Loading Ramps (3000x360x2500kg)

£900.00

£750.00

Aluminium Loading Ramps (2500x360x3800kg)

£852.00

£710.00

Aluminium Loading Ramps (2500x300x2000kg)

£672.00

£560.00

Aluminium Loading Ramps (2000x300x2700kg)

£624.00

£520.00

Aluminium Loading Ramps (3000x510x12000kg)

£1,962.00

£1,635.00

Aluminium Wheel Risers

From

£1,308.00

£1,090.00

Aluminium Van Loading Ramps - 500mm Wide

From

£954.00

£795.00