Ground protection: Composite mats vs. plywood boards

Whether it’s to provide a temporary roadway at a works site or providing pedestrian walkways at festivals, ground protection mats are essential in many industrial type settings. Because they’re used in potentially dangerous areas and in adverse weather conditions such as muddy areas or sites with heavy machinery it’s important that ground protection is both strong and durable. Unfortunately, because it’s often considered cheap and easy to handle, plywood boards are often used as ground protection despite the main downsides that make this solution unsuitable.

Comparing plywood boards to composite mats

Plywood is the most popular and cheapest form of wood ground protection and comes in various forms including softwood, hardwood, solid or laminated plywood. It’s usually used for steel tracked vehicles and is reasonably cheap to buy from the outset making it a popular choice of ground protection.

The reality is that plywood could end up costing significantly more over time and is generally unsafe and unreliable to use, especially in demanding industrial settings. A simple comparison of plywood boards verses proper ground protection reveals why.

The cons of using plywood

While plywood may be lightweight and cheap to buy to begin with, there are many downsides to this type of ground protection which ultimately make it unsuitable.

Plywood damage

The porous structure of plywood means that it can absorb a lot of water which accelerates rotting and deteriorates the wood over time, plus it can absorb and even leach other oils, fluids and chemicals posing a serious cross-contamination risk. Plywood is also at risk of becoming infested with rodents, insects and bacteria and fungi, especially once rotting sets in which also causes the wood to deteriorate.

Unreliable capacities

The average load bearing capacity of plywood mats can vary over time and from sheet to sheet depending on the differences in density, quality, ground weather and overall usage conditions of the wood which causes deterioration at varying rates. This can be a real problem when working with different types of vehicles and machinery.

Safety hazards

Plywood mats can also be a serious safety hazard. Not only is there a risk of splinters and debris which could cause trips and accidents, but the danger of rot and other deterioration could cause them to bend or break unexpectedly. This is extremely problematic for work sites and other industrial settings that need to adhere to strict health and safety practices. They’re also notoriously slippery when wet and can suffer from frost and ice which are serious safety hazards.

Cost!

Rot and deterioration also mean plywood boards have a very limited lifespan and ultimately cost a lot more in maintenance and replacement not to mention the hassle of constantly re-ordering plywood boards at different times.

Replace your plywood boards with composite mats

Composite mats like TuffTrak ground protection solutions are designed to answer all the failures of plywood boards for a safer and ultimately much more cost-effective alternative.

Damage resistant

Opting for ground protection mats made from 100% recycled high-density polyethylene ensures minimal risk of damage from the outset for a longer lasting solution. This material is chemically inert so there’s no risk of cross-contamination from chemicals, oils and fluids and is completely water resistant so there is no damage over time from absorption so no risk of rotting, rodents or other deterioration. This material is also easy to clean and maintain so you can keep your ground protection mats in good condition.

Consistent quality

Each mat is constructed to the same consistent quality and can reliably hold the right loading capacity depending on the mats you opt for. With TuffTrak solutions you can find heavy duty mats capable of handling up to 600psi. Because they’re water and weather resistant you can trust your mats to hold the right load capacity time after time.

Safety first

Opting for ground protection that is reliably durable and weather resistant guarantees safety no matter the season or location. Our TuffTrak mats, for example, use a special aggressive diamond cleat tread for superior traction and grip to help ensure safety at all times. Unlike plywood, they won’t splinter or bend even in adverse conditions but are still lightweight and easy to handle so they can be man-deployed with minimal risk of injury.

Cost effective

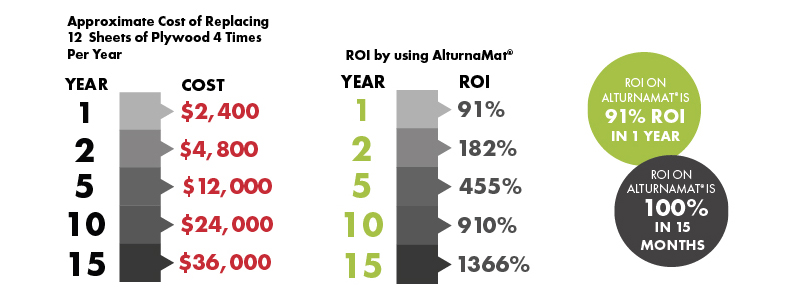

With a much longer lifespan and superior quality, it’s no surprise that you’ll save money by maintaining and keeping these mats for many years to come even with frequent and hard wearing industrial use. In fact, comparing ordinary plywood and one of the most popular mats from the TuffTrak range, superior ground protection could earn back plywood replacement costs and provide ROI in less than 15 months.

Superior ground protection

Ready to swap out your old and damage plywood for long-lasting, quality ground protection? Take a look at our full ground protection range.