Plant Ramp Buying Guide

Whether you're a JCB, Hitachi or John Deere fan, you will understand the importance of safely loading your machinery into vehicles and up heights. Our heavy duty Aluminium Loading Ramps are the perfect solution. Due to the value of the machinery being loaded, and to ensure the safety of the driver and those around, it is essential you purchase the correct ramps for your load height and the capacity you plan to load.

This guide will walk you through everything you need to know before buying heavy duty loading ramps designed for loading tracked or wheeled machinery. We’ll look at what to check before purchasing a ramp, key features to consider and how to ensure you load your equipment safely, without damaging your machinery or yourself. Whether you’re looking for ramps to load your dumper truck, excavator or digger into your trailer, or a forklift into a container, our guide is here to help.

What To Check

Measure the vertical height from the ground to where the ramp will rest when in place.

Check the useable width of the van, trailer or container to check the space available for the ramp to rest.

Check the maximum weight of the machine and any weight it will be carrying including the driver and fuel.

Tips & Recommendations

When buying a pair of loading ramps, it is essential you check your load height, from the ground to where the ramp will rest, as this identifies the required ramp length. In line with EU recommendations, the maximum loading gradient is 1:33. The plant ramps for trucks and vans are built with this gradient in mind. Our container ramps and car loading ramps offer a slightly smoother gradient as cars and forklifts often require a smoother slope.

For items with low clearance, such as forklifts, low-clearance cars and scissor lifts, a smoother gradient is usually required. If you are loading an item with low ground clearance, please speak to our team. We can carry out a CAD simulation to check suitability based on what machine you are loading and the height you are going up. Where a smoother gradient is required the ramps can be custom cut to meet your needs.

Things to consider

Check the wheel or track type of your machine. For rubber tracks and wheels aluminium ramps are generally recommended. For steel tracks rubber coated ramps or a milled surface is required.

Check the ramp weight is suitable for the person who is due to lift the ramps. Carry handles can be added if needed.

Check your wheelbase - look at the vehicle from side view, the distance between the centre of front wheel and rear wheel (rim centre) is your wheelbase. As wheelbase reduces the capacity the ramp can hold often also reduces.

Consider the storage space available, such as the useable length or bed of the truck or trailer if you plan to store the ramps in your vehicle.

As standard the loading ramps have a rest on connection which is ideal for flat bed vehicles. We offer 4 connection options to ensure your ramp remains securely in place.

Plant ramps have a minimum and maximum track width they are designed for. This ensures the weight is spread across the surface to improve the life expectancy of the ramp.

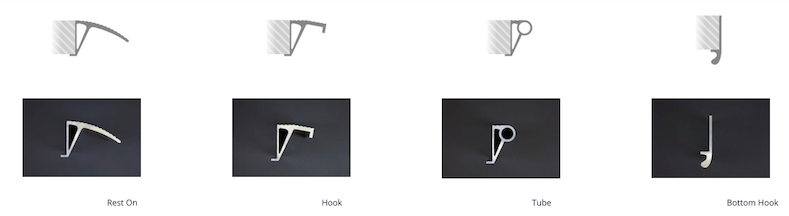

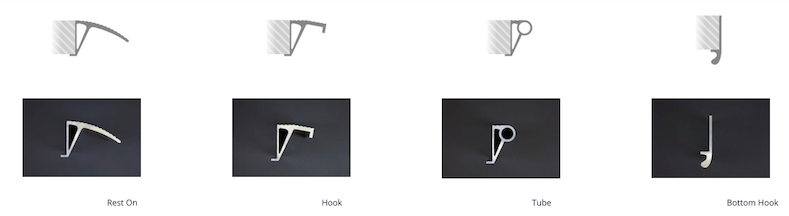

Connection Options

At The Ramp People we offer 4 different connection options as we understand all vehicles are not the same. The standard, most popular connection is the rest-on connection. This connection simply curves and rests on the back of the vehicle. There is a pre-drilled hole to allow you to place a pin through the ramp to hold it onto the vehicle for extra security. Rest on connections are perfect for flatbed vehicles such as transit vans or tipper trucks. They are also perfect for use on containers and kerbs. Alternative connections include the hook connection (for beaver tail trailers), tube and bottom hook (step frame trailers).

For loading into vans and trailers, The Ramp People offer an extensive range of plant machinery ramps in lengths from 1.5m to 5.5m with capacities up to 58,000kg. Provided as a pair for ease of loading, the aluminium loading ramps are all TÜV certified to allow you to load with confidence and are offered with a 2-year warranty. The loading ramps can be customised when required. The range includes solutions for rubber tracked machinery and steel tracked machinery.

Types of Plant Ramps for Loading into Vans & Trailers

- Lengths from 1.5m to 5.5m, load at heights up to 1.6m

- Capacities up to 20,000kg across the pair

- Load rubber tracked machinery and rubber wheels

- Widths from 300mm to 580mm per ramp

- Provided as a pair, lightweight design

- Made in Europe, TÜV certified

- Lengths from 1.5m to 4m, load at heights up to 1.2m

- Capacities up to 4,500kg across the pair

- Load lightweight garden and plant machinery

- R13 slip resistance for optimum grip

- Made in Europe - TÜV certified

- Not recommended for tracked machinery

- Lengths from 1m to 5.5m, load at heights up to 1.6m

- Solutions with rubber coating or a milled surface

- Capacities up to 58,000kg across the pair

- Load industrial steel tracked machinery

- 380mm - 720mm wide solutions for safe loading

- Made in Europe - TÜV certified

- 11m length for a smooth gradient, ideal for forklifts

- Adjustable to meet your container height

- Capacities up to 13,000kg, heavy-duty design

- Safely unload and load shipping containers

- Easy to manoeuvre using a forklift

- Made in Europe - CE marked

Aluminium Plant Ramps

- 1.5m to 5.5m lengths, for heights up to 1.6m

- Capacities up to 20,000kg across the pair

- Load machinery with rubber tracks or rubber wheels

- Widths from 300mm to 580mm wide

- Provided as a pair, lightweight design

- Made in Europe, TÜV certified

Sabretooth Ramps

- Lengths from 1.5m to 4m, load at heights up to 1.2m

- Capacities up to 4,500kg across the pair

- Load lightweight garden and plant machinery

- R13 slip resistance for optimum grip

- Made in Europe - TÜV certified

- Not recommended for tracked machinery

Ramps for Steel Tracked Machinery

- Lengths from 1m to 5.5m, load at heights up to 1.6m

- Solutions with rubber coating or a milled surface

- Capacities up to 58,000kg across the pair

- Load industrial steel tracked machinery

- 380mm - 720mm wide solutions for safe loading

- Made in Europe - TÜV certified

Yard Ramps

- 11m length for a smooth gradient, ideal for forklifts

- Adjustable to meet your container height

- Capacities up to 13,000kg, heavy duty design

- Safely unload and load shipping containers

- Easy to manoeuvre using a forklift

- Made in Europe - CE marked

For loading into containers, over steps or overcoming smaller heights in the warehouse, we offer a range of container ramps. The ramps are built to a smoother gradient, perfect for loading forklifts, cars and tracked machinery.

Plant Ramps for Containers, Steps and Lower Heights

- Lengths from 0.5m to 2m, load at heights up to 400mm

- Capacities up to 7,500kg across the pair

- Load rubber tracked machinery and forklifts

- Lightweight and portable design, easy to use

- Made in Europe, TÜV certified

- Safely overcome heights from 150mm - 300mm

- 2.2m wide, covers the full container width

- 10,000kg capacity, ideal for forklifts, cars and machinery

- Smooth gradient for ease of loading

- Modular design, easy to assemble and remove

- Lengths from 1.5m to 4m, load at heights up to 600mm

- Capacities up to 2,900kg across the pair

- Load cars, ride-on mowers and lightweight machinery

- Lightweight and portable design, easy to use

- Made in Europe, TÜV certified

- Safely overcome heights from 140mm - 300mm

- 2.2m wide, covers the full container width

- 8,000kg capacity, ideal for forklifts and machinery

- Smooth gradient for ease of loading

- Steel chains to secure during loading

Aluminium Container Ramps

- Lengths from 0.5m to 2m, load at heights up to 400mm

- Capacities up to 7,500kg across the pair

- Load rubber tracked machinery and forklifts

- Lightweight and portable design, easy to use

- Made in Europe, TÜV certified

Rubber Container Ramp

- Safely overcome heights from 150mm - 300mm

- 2.2m wide, covers the full container width

- 10,000kg capacity, ideal for forklifts, cars and machinery

- Smooth gradient for ease of loading

- Modular design, easy to assemble and remove

Car Ramps

- 1.5m to 4m lengths, for heights up to 600mm

- Capacities up to 2,900kg across the pair

- Load cars, ride-on mowers and lightweight machinery

- Lightweight and portable design, easy to use

- Made in Europe, TÜV certified

Wide Container Loading Ramp

- Suitable for areas with limited space

- Turning platforms available

- Designed for heights from 38mm - 160mm

- Modular system to meets your needs

- Manufactured in Sweden to the highest standards, 2 year warranty

Care & Maintenance

- The ramps require little maintenance, they can simply be wiped clean with a damp cloth when needed. The aluminium ramps are offered with a 2 year warranty.

- It is important to regularly inspect your loading ramp for any signs of damage or wear. If you notice any issues, contact the manufacturer for advice to ensure the ramp remains safe to use. Never use a ramp that is damaged, as this could pose a safety risk.

- When ramps are used in a commercial / workplace setting, they should be inspected regularly in accordance with the Provision and Use of Work Equipment Regulations 1998 (PUWER).

Assembling, Positioning & Use

- The loading ramps are designed to secure to the vehicle. When a rest on connection is selected, the ramps are provided with a pre-drilled hole to allow you to secure the ramp to the vehicle during loading. A security plate is also provided for when tailgates are used. For higher capacities, a chain is provided. Where a hook connection is chosen, the hook is designed to hook into a channel or metal bar, for instance on a beaver tail trailer. Please view your ramp's user manual for full instructions prior to use.

- It is important the top and foot of the ramp sits securely on a flat area for support. The foot of the ramp is angled to ensure it securely sits on the ground, do not exceed the recommended minimum or maximum load height as the ramp will not sit securely on the ground.

- The heavy-duty loading ramps should be used in line with the recommended guidance stated on the website and the user guides provided with the ramp. It is important not to exceed the recommended safe working load (SWL) or load height as it can damage the ramp. If you have any questions around suitability please contact our team.

- Where the ramp is used in the workplace, a Health and Safety assessment should be undertaken if employees are required to lift the ramp. Companies should act in line with Manual Handling Operations Regulations and Lifting Operations and Lifting Equipment Regulations (LOLER). Personal Protective Equipment (PPE), such as safety shoes and gloves, should be worn when carrying or using the ramps.

Customisation Solutions

At The Ramp People, we offer customised loading ramps to meet your specific requirements. Customisation options include adjusting the ramp’s load height for a smoother gradient, adding safety edges, modifying the width, and incorporating carry handles for easier transport.

If you are loading an item with low ground clearance, such as scissor lifts and cleaning machines, or you are loading a machine with an unbalance weight distribution, or you are unsure whether a ramp will work for your vehicle, our factory can assess suitability before purchase. Using CAD simulation, we can model your loading situation to ensure the ramp is fit for purpose.

For advice, suitability checks, or bespoke solutions, please contact our team. We are here to help you find the perfect ramp for your needs.

Request a callback

Still need assistance? Our team is available throughout the week to help via phone, email, live chat or WhatsApp. If you’d rather we call you, you can easily request a callback here.